- Home Page

- Company Profile

-

Our Products

- Plate Rolling Machine

- Shearing Machine

- Hydraulic Press

- Metal Sheet Straightening Machine

- Hydraulic Press Brake Machine

- Sheet Straightening Machine

- Industrial Machinery

- Plate Straightening Machine

- Plate Bending Machine

- Hydraulic with Pre Pinching type Plate Rolling Machine

- Mechanical Plate Rolling Machine

- Sheet Rolling Machine

- 3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine

- Fully Hydraulic Pre-Pinching Type Plate Rolling Machine

- Semi Hydraulic Plate Bending Machine

- 3 Phase Stainless Steel Plate Rolling Machine

- Hydraulic 3 And 4 Roll Plate Bending Machine

- Hydraulic Plate Bending Machine

- SHEET ROLLING MACHINE

- Our Clients

- Contact Us

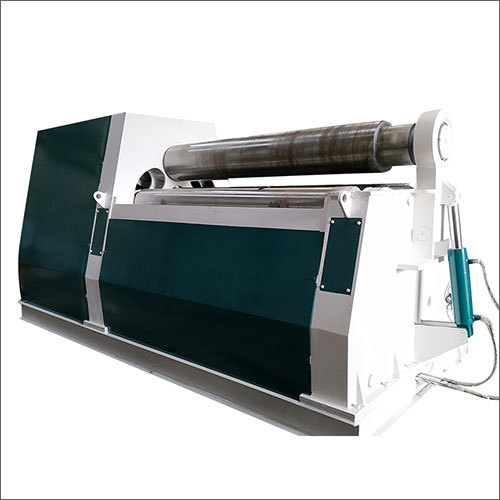

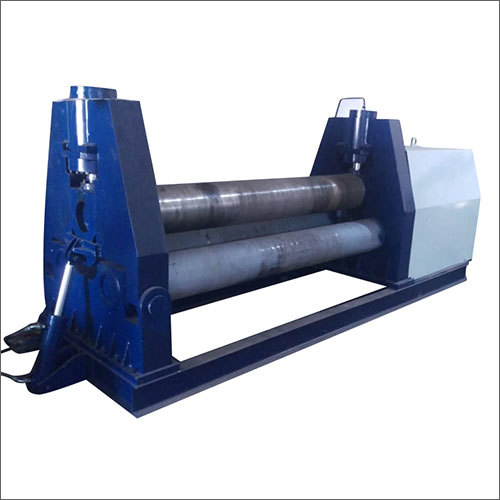

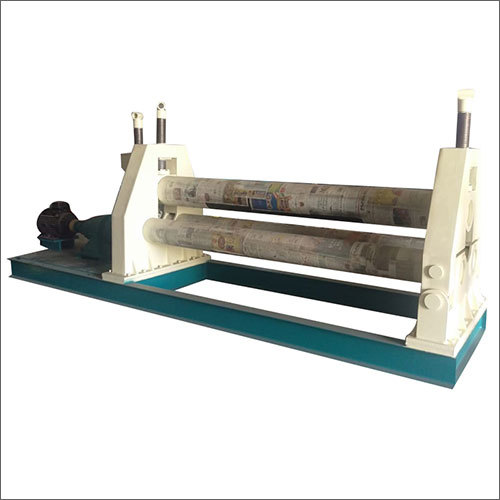

Plate Rolling Machine, Mechanical type

250000 INR/Unit

Product Details:

- Operating Temperature Ambient

- Frame Type Rigid frame

- Connectivity Options None

- Control System Mechanical

- Power Rating Depends on motor size

- Accuracy High

- Lubricating System Manual lubrication

- Click to view more

X

Plate Rolling Machine, Mechanical type Price And Quantity

- 1 , , Number

- 250000 INR/Unit

Plate Rolling Machine, Mechanical type Product Specifications

- Plate Rolling Machine

- Heavy-duty construction High precision rolling

- 12 months

- Paint-coated

- Rolling metal sheets

- Electric drive Horsepower (HP)

- Standard industrial voltage (e.g. 220V or 440V)

- Varies based on model

- Mechanical

- Low noise operation

- Depends on sheet thickness and size

- None

- White and Green

- Manual lubrication

- Depends on motor size

- Mechanical

- High

- Electric

- Rigid frame

- Customizable

- None

- Rolling Machine

- Manual or semi-automatic

- Ambient

Plate Rolling Machine, Mechanical type Trade Information

- Ex-Ahmedabad

- 5 , , Number Per Month

- 20 Days

- Sample costs shipping and taxes has to be paid by the buyer

- standard plastic packing

- All India

Product Description

Mechanical Plate Rolling Machine that we are offering is widely acclaimed among our customers owing to its high build quality, sturdy construction, and longevity. This machine is well designed and developed in our ultra-advanced production site making the best use of pioneering in-house tools and techniques. Owing to its reliable performance and resilience, we are seeing a huge demand for the Mechanical Plate Rolling Machine in the marketplace.

Mechanical Plate Bending Machine is one of the most cost effective solutions for a small fabrication workshop. It is a 3 Roll Pyramid type Plate Bending Machine with planetary gearbox.

Mechanical symmetrical rolling machine is a kind of three roller sheet rolling machine. The upper roll moves vertically in the center between the two lower rolls. The two lower rolls rotate and provide the plate materials with torque.

The Pyramid Type Mechanical plate bending machine consists of two parts, the operation part and the transmission part. The transmission part is welded at the whole bottom pallet. It features compact structure, easy operation and convenient maintenance. Mechanical Plate rolling machine is mainly used in the process of cold working. The mechanical plate bending machine is widely used in boiler, chemical industry, mining, construction, shipbuilding and other machinery industries.

Specification

|

Power |

Electric |

|

Machine Type |

Hot Rolling |

|

Max Bending Radius |

0-50 mm |

|

Phase |

Three Phase |

|

Brand |

Viraat |

|

Material |

Mild Steel |

i

Precision Rolling for Industrial Applications

This plate rolling machine ensures uniform and precise shaping of metal sheets, making it invaluable for industries requiring high accuracy and consistency. The robust frame and manual lubrication system add to its longevity, allowing sustained performance even under demanding workloads. Its adaptability to varying sheet thickness and size provides manufacturers with exceptional flexibility.

Adaptive Design and Heavy-Duty Capabilities

Customizable dimensions and a solid, rigid frame make this machine versatile for different operational spaces and project requirements. Its electric drive system ensures smooth operation while the painted surface protects against industrial wear, maintaining a dependable workspace with minimal noise output.

FAQ's of Plate Rolling Machine, Mechanical type:

Q: How does the mechanical plate rolling machine operate?

A: The mechanical plate rolling machine uses an electric drive to power its rolling mechanism, combined with manual or semi-automatic operation. Operators can control adjustments mechanically, ensuring precise shaping of metal sheets according to specified requirements.Q: What types of sheet metals can be processed with this machine?

A: This machine is suitable for a wide range of metal sheets, with its production capacity and rolling thickness depending on the chosen model. It's ideal for mild steel, stainless steel, aluminum, and similar metals commonly used in industrial fabrication.Q: When should manual lubrication be performed on the machine?

A: Manual lubrication should be carried out regularly as part of routine maintenance, following the manufacturer's guidelines. This ensures smooth operation of moving parts and prolongs the machine's lifespan.Q: Where is this plate rolling machine commonly used?

A: It is widely used in metal fabrication workshops, fabrication plants, and manufacturing units, especially in industries involving structural steel, shipbuilding, and construction components, primarily across India.Q: What is the process for adjusting the rolling thickness?

A: The operator adjusts the rolls mechanically according to the material thickness and required curvature. These settings are determined prior to each rolling operation to achieve accurate and consistent results.Q: What are the main benefits of using this plate rolling machine?

A: Key benefits include high precision, low noise operation, heavy-duty construction, customizable size, and a paint-coated surface for enhanced durability. It is reliable for consistent high-quality output with minimal maintenance requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email