- Home Page

- Company Profile

-

Our Products

- Plate Rolling Machine

- Shearing Machine

- Hydraulic Press

- Metal Sheet Straightening Machine

- Hydraulic Press Brake Machine

- Sheet Straightening Machine

- Industrial Machinery

- Plate Straightening Machine

- Plate Bending Machine

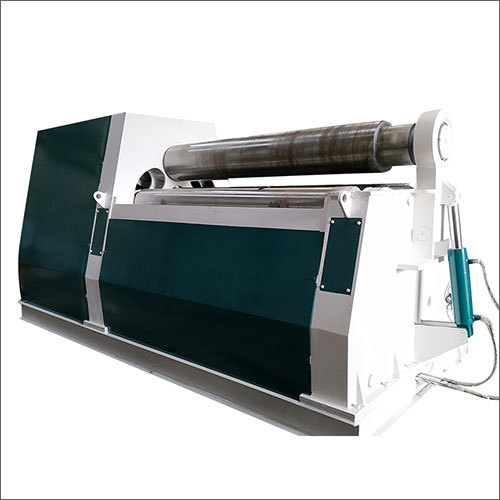

- Hydraulic with Pre Pinching type Plate Rolling Machine

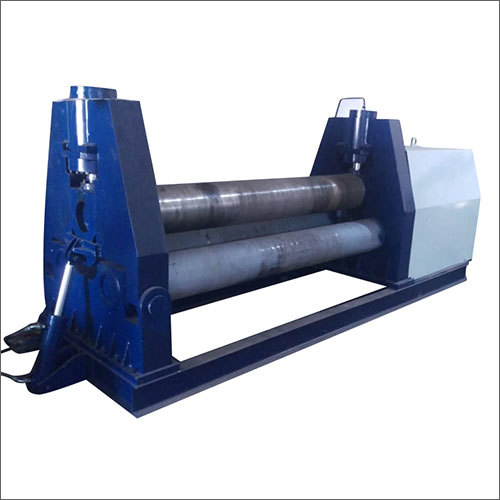

- Mechanical Plate Rolling Machine

- Sheet Rolling Machine

- 3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine

- Fully Hydraulic Pre-Pinching Type Plate Rolling Machine

- Semi Hydraulic Plate Bending Machine

- 3 Phase Stainless Steel Plate Rolling Machine

- Hydraulic 3 And 4 Roll Plate Bending Machine

- Hydraulic Plate Bending Machine

- SHEET ROLLING MACHINE

- Our Clients

- Contact Us

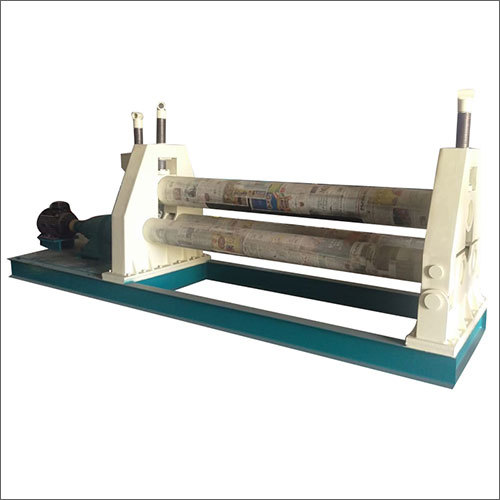

Plate Rolling Machine

1150000 INR/Number

Product Details:

- Machine Type Plate Rolling Machine

- Motor Power 7.5 HP

- Accuracy 0.5 mm

- Frequency 50 Hz

- Control System Push Button Panel Control

- Noise Level < 75 dB

- Connectivity Options No external connectivity

- Click to view more

X

Plate Rolling Machine Price And Quantity

- 1150000 INR/Number

- 1 Number

- 850000.00 - 5400000.00 INR/Number

- 50-55 HRC

- Alloy Steel/High-Strength Steel

- Included

- Forged Steel

- 4 m/min

- Equipped

- Yes, for Roll Adjustment

- 2500 mm

- 3

- Epoxy Coated

- Yes

- Provided for Operator Safety

- 225 mm

- 16 mm

Plate Rolling Machine Product Specifications

- 0.5 mm

- 7.5 HP

- 3500 kg

- Plate Rolling Machine

- 10 Horsepower (HP)

- Semi Automatic

- 6-8 Tons/Day

- 210 Bar

- Push Button Panel Control

- 50 Hz

- < 75 dB

- Rolling and forming of metal plates into cylindrical shapes

- PRM-4260

- Heavy Duty Construction, Easy Operation, Durable Gears

- No external connectivity

- Polished

- Other

- Electricity

- Robust Welded Steel Structure

- 415 V

- 4200 x 1500 x 1450 mm

- Air Cooled

- Blue & Black

- Other

- 5C to 45C

- Manual Greasing

- Electric Motor with Gearbox

- 10 kW

- 50-55 HRC

- Alloy Steel/High-Strength Steel

- Included

- Forged Steel

- 4 m/min

- Equipped

- Yes, for Roll Adjustment

- 2500 mm

- 3

- Epoxy Coated

- Yes

- Provided for Operator Safety

- 225 mm

- 16 mm

Plate Rolling Machine Trade Information

- Ex-Ahmedabad

- Cheque, Letter of Credit (L/C)

- 100 Number Per Month

- 8 Week

- Asia, Middle East, Africa

Product Description

Plate Bending Machine

Plate Bending machineis used to bend or roll the straight plates in to round & cylindrical shape.

VIRAAT INDUSTRIESis the leading supplier of Plate bending machine in INDIA, UAE, Qatar, and many African countries.

Plate Bending machines are classified many types as below:

01)Hydraulic Plate Bending Machine

02)Mechanical Plate bending machine

03)Hydro mechanical Plate bending machine

04)3 roll & 4 roll Plate bending machine

05)Variable Geometry plate bending machine

06)Double pre pinch Plate rolling machine

07) PLC operated automatic plate bending machine

As per different application of customers we provided best match solution from mentioned plate bending machines.

Our machines follows international standard process & procedures like

ST52 plate body structures

Induction hardened rolls

Stress releived welded frames

self aligned bearings

Sand blasted surfaces with powder coated component

NC controller

Branded hydraulic parts

Hydro motors & Planetary gearboxes

Efficient and Accurate Plate Forming

The PRM-4260 operates at a working speed of 4 meters per minute and delivers ultra-precise results, achieving measurements accurate to within 0.5 mm. Its powerful 10 HP electric motor, coupled with a high-strength, forged steel main shaft, makes it suitable for high-volume production needs. The pre-bending function enables flawless edges and enhances the quality of the finished product.

Operator Safety and User-Friendly Design

Equipped with a protective cover and an emergency stop, the machine prioritizes operator safety. The push-button panel control simplifies operation, while manual greasing ensures the smooth running of internal components. The air-cooled system maintains stable performance, even during continuous heavy-duty use, and the polished, epoxy-coated frame resists wear for long-lasting reliability.

FAQ's of Plate Rolling Machine:

Q: How does the plate rolling process work on the PRM-4260 machine?

A: The PRM-4260 uses three precisely-aligned rolls to bend metal plates into cylindrical shapes. You load the plate, use the hydraulic system for roll adjustment, and operate the semi-automatic controls to guide the plate through the rolling process, which also allows for pre-bending edges for higher-quality results.Q: What types of materials can this plate rolling machine handle?

A: This machine is constructed using alloy or high-strength steel for durability and is capable of working with a variety of metal plates within 16 mm thickness and up to 2500 mm width. It's suitable for medium to heavy metal fabrication projects, ensuring reliable performance with most industrial-grade metals.Q: When should manual greasing be performed for maintenance?

A: Manual greasing should be done regularly according to the instruction manual provided with the machine. For optimal performance and durability, it's recommended to inspect and lubricate all moving parts before each operation or as outlined in the scheduled maintenance plan.Q: Where is the PRM-4260 commonly used?

A: This machine is widely utilized in industries such as metal fabrication, manufacturing, and shipbuilding across India and global markets, making it ideal for creating cylindrical components like tanks, cones, and pipes from flat metal plates.Q: What are the main benefits of the PRM-4260 plate rolling machine?

A: Key advantages include precise rolling accuracy (0.5 mm), robust and durable construction, safety features like an emergency stop, user-friendly controls, and a high production capacity of 6-8 tons per day. Its semi-automatic operation reduces manual labor while ensuring operator safety.Q: How can operators ensure safe usage of the plate rolling machine?

A: Operators should always use the provided protection cover, follow the instruction manual strictly, and utilize the emergency stop in case of any irregular operation or emergency. Routine inspections and adherence to safety protocols are essential for risk-free operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email