- Home Page

- Company Profile

-

Our Products

- Plate Rolling Machine

- Shearing Machine

- Hydraulic Press

- Metal Sheet Straightening Machine

- Hydraulic Press Brake Machine

- Sheet Straightening Machine

- Industrial Machinery

- Plate Straightening Machine

- Plate Bending Machine

- Hydraulic with Pre Pinching type Plate Rolling Machine

- Mechanical Plate Rolling Machine

- Sheet Rolling Machine

- 3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine

- Fully Hydraulic Pre-Pinching Type Plate Rolling Machine

- Semi Hydraulic Plate Bending Machine

- 3 Phase Stainless Steel Plate Rolling Machine

- Hydraulic 3 And 4 Roll Plate Bending Machine

- Hydraulic Plate Bending Machine

- SHEET ROLLING MACHINE

- Our Clients

- Contact Us

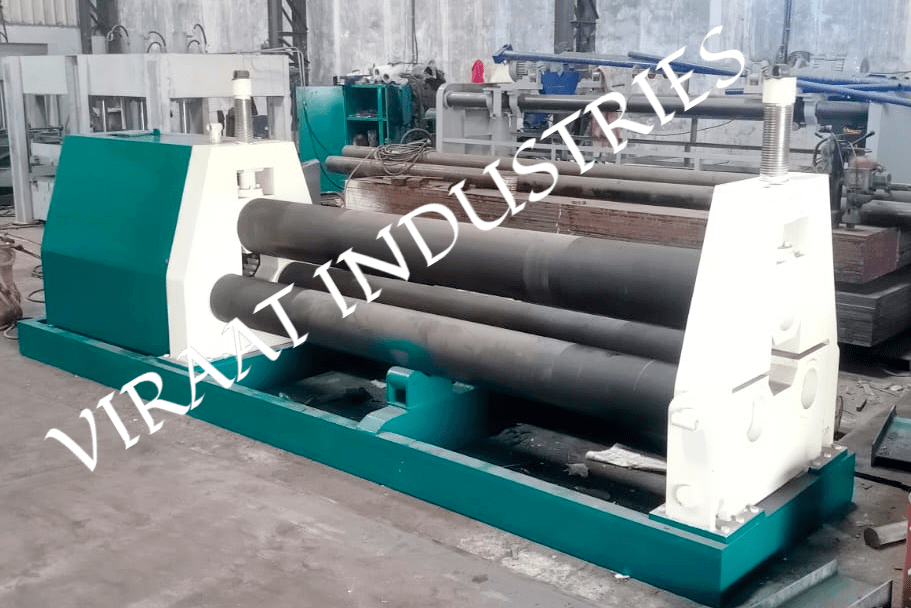

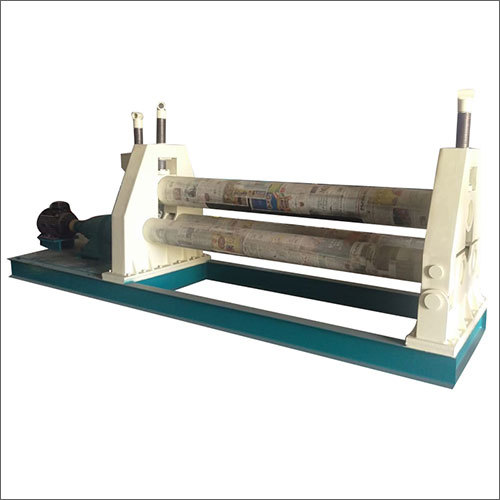

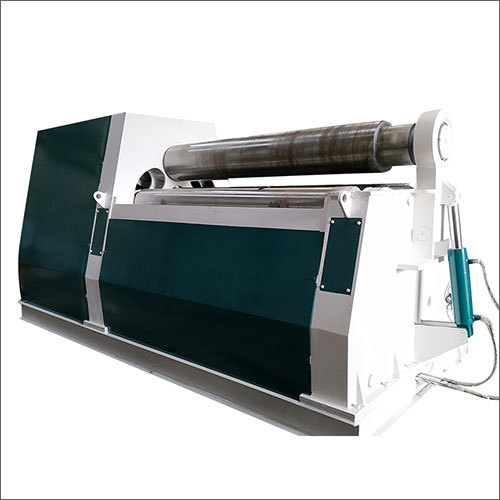

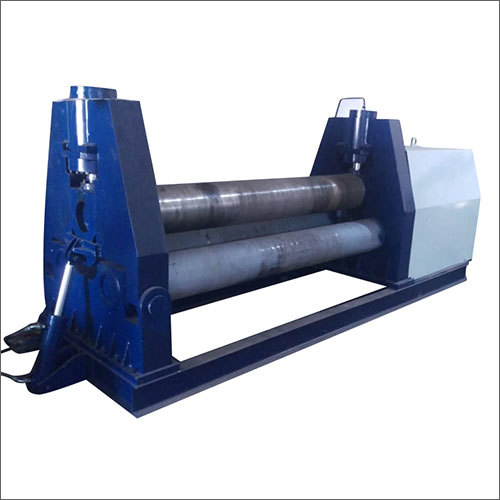

3 Roller Plate Bending Machine

460000.0 INR/Unit

Product Details:

- Machine Type Hydraulic, Semi-Hydraulic and Mechanical type

- Cooling System Water

- Lubricating System Manual

- Model No VH3 and VH4 and 3M and 3HM

- Country Of Origin Made In India

- Power Source Hydraulic

- Operating Type Semi Automatic

- Click to view more

X

3 Roller Plate Bending Machine Price And Quantity

- 1 Unit

- 460000.0 INR/Unit

3 Roller Plate Bending Machine Product Specifications

- Hydraulic

- 12-18 MONTHS

- 2-5 Ton

- Painted

- Pressure Vessels, Oil & Gas Industry, Shipbuilding, Power Plants, Water tanks, Boilers, Storage tanks

- 150 N/cm2

- Made In India

- Semi Automatic

- VH3 and VH4 and 3M and 3HM

- Manual

- Water

- 440 Volt (v)

- Hydraulic, Semi-Hydraulic and Mechanical type

3 Roller Plate Bending Machine Trade Information

- Ex-Ahmedabad at our factory

- 50 Unit Per Year

- 8 Week

- No

- Asia, Middle East, Africa

- All India

Product Description

Plate Bending Rolling Machine Hydraulic Plate Rolling Machine - NC Controlled Apart from conventional Hydraulic Plate Rolling Machine VIRAAT does automation to the Sheet Bending Machine and manufacture Automatic Plate Rolling Machine. The automation can be done as per your application and requirement. This automation can optimize the speed and performance of Hydraulic Plate Rolling Machine.

Automatic Plate Rolling Machine is controlled by Programmable Logic Control (PLC). This machine is also known as NC Hydraulic Plate Rolling Machine. As per the latest trends in the industry we use Epicyclic Planetary Gearbox in the machine. These planetary drive is directly mounted on top roll. It gives higher torque compared to conventional helical gearbox. We use brake motor instead of normal electric motor. Brake motor helps the machine to stop the machine at any point of bending process. Semi - Automatic Plate Rolling Machine - NC Controlled Automatic Plate Rolling Machine is provided with electronic digital readouts. These digital readouts mounted in the portable control station. The operator can set value to stop the roll at desired position. The positioning controller automatically stops the roll movement of Plate Roller when the roll reached to it. The system is designed to make repetitive bends. This arrangement enhance productivity, specially for conical rolling components. Automatic Plate Rolling Machine (NC Controlled)

This type of Sheet Bending Machine is supplied with NC Controller. The NC Controlled Automatic Plate Rolling machine is an advance version for more precise control. The operator desk is movable. We offer PLC Based controller of reputed manufacturers like Siemens, Delta, Schneider etc. In Automatic Plate Rolling Machine, the operator can set the program the top and bottom positions of bending rolls. These programs are saved in the memory and can be reloaded as and when required. We provide machine with 100 program memories with color LCD display and keyboard. The operator console has both the options of touch panel as well as keyboard.

AUTOMATIC PLATE ROLLING MACHINE FEATURES

- Digital Readouts to Check the roll position

- NC Controller automatic stop the roll at the limit set

- Bottom rolls are hydraulically driven independently.

- Color LCD Display of roll positioning

- Can be operated by touch panel & keyboard

- 100 Program can be saved and reloaded the recipe.

- Movable operating desk with user friendly interface

- Hydraulic powered bending roll adjustment.

- Push button Hydraulic powered pinch roll adjustment.

- Push button Hydraulic swing arm for finished part removal.

- Push button pendant control of forward/reverse.

- Spherical roller bearings on all 3 roll shafts.

- Main Drive motor is Electric Brake Motor

- Emergency Stop Switch to stop machine during operation

- Heavy duty reinforced welded steel frame.

- Programmable Logic Controller (PLC)

- HMI With Color Display

- Linear Motion Guideways

- Movable Operating Desk with Touch Pad & Keyboard

- Solid Rolls of EN 8/9 with material test certificates

- Epicyclic Planetary Gearbox for extra torque

- Variable Frequency drive, with control panel (VFD)

- 2 Electric motors with reputed ISO brand

- Complete hydraulic system with power pack & cylinders

- Hydraulic cylinder is double acting made from carbon steel seamless pipe.

- Spherical roller bearings on all 3 roll shafts.

- M C B to protect machine against short-circuit and over-loading.

- Emergency Stop Switch is fitted on control panel to avoid any Accident.

Additional Information:

- Production Capacity: 10-100 mm thickness

- Delivery Time: 6-8 Weeks

- Packaging Details: Standard Plastic Packing

Versatile Applications Across Industries

Engineered for a broad range of requirements, the 3 Roller Plate Bending Machine excels in industries such as pressure vessel manufacturing, oil & gas, shipbuilding, power plants, and storage solutions. Its precise rolling capabilities enable fabrication of complex cylindrical forms essential for tanks, boilers, and various industrial containers.

Advanced Technology for Efficient Bending

This machine incorporates hydraulic, semi-hydraulic, and mechanical operating types, paired with a semi-automatic control system. The 440 Volt power source and manual lubrication ensure smooth operation, while the water cooling system protects critical components during intensive use.

Rugged Design, Reliable Performance

With a sturdy construction, painted surface treatment, and capacities up to 5 tons, this rolling machine guarantees durability under heavy workloads. Supported by a 12-18 month warranty, users benefit from reliable output and minimal maintenance downtime, making it a valuable asset for industrial production.

FAQ's of 3 Roller Plate Bending Machine:

Q: How does the 3 Roller Plate Bending Machine operate in industrial settings?

A: This machine functions by positioning the metal plate between three robust rollers, which apply pressure and gradually curve the material to the desired cylindrical or conical shape. The process can be managed semi-automatically, allowing operators to ensure precision and safety.Q: What applications is this machine best suited for?

A: The 3 Roller Plate Bending Machine is ideal for pressure vessels, oil and gas industry components, shipbuilding parts, boilers, storage tanks, and water tanks, due to its ability to handle substantial metal thicknesses and achieve accurate curvatures.Q: When should I choose a hydraulic versus a mechanical model?

A: Hydraulic models offer greater control and are preferred for heavy-duty or high-precision work, while mechanical versions are suitable for lighter or standard rolling tasks. Selection depends on your production volume and material specifications.Q: Where is this machine manufactured and exported from?

A: This rolling machine is manufactured in India and is available for both domestic and global export, offered by established suppliers, manufacturers, and service providers.Q: What is the process for maintaining this plate bending machine?

A: Routine maintenance includes manual lubrication of moving parts and ensuring the water cooling system is operational. These steps are crucial to prolong the machine's lifespan and maintain its performance.Q: How does the warranty benefit buyers?

A: The 12-18 month warranty provides users with peace of mind, covering defects in materials or workmanship and ensuring support in the unlikely event of operational issues during early use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email