- Home Page

- Company Profile

-

Our Products

- Plate Rolling Machine

- Shearing Machine

- Hydraulic Press

- Metal Sheet Straightening Machine

- Hydraulic Press Brake Machine

- Sheet Straightening Machine

- Industrial Machinery

- Plate Straightening Machine

- Plate Bending Machine

- Hydraulic with Pre Pinching type Plate Rolling Machine

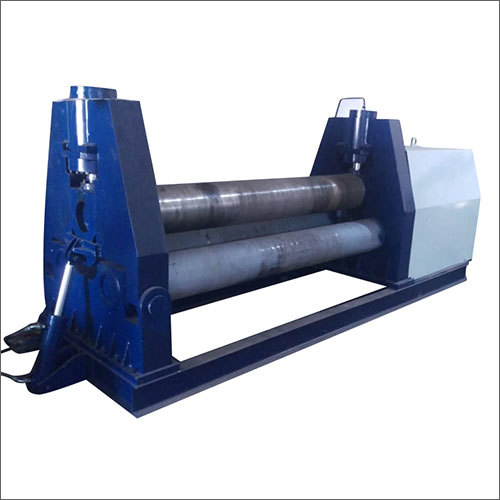

- Mechanical Plate Rolling Machine

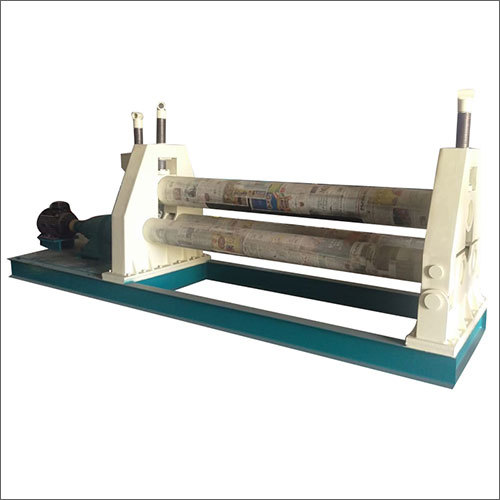

- Sheet Rolling Machine

- 3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine

- Fully Hydraulic Pre-Pinching Type Plate Rolling Machine

- Semi Hydraulic Plate Bending Machine

- 3 Phase Stainless Steel Plate Rolling Machine

- Hydraulic 3 And 4 Roll Plate Bending Machine

- Hydraulic Plate Bending Machine

- SHEET ROLLING MACHINE

- Our Clients

- Contact Us

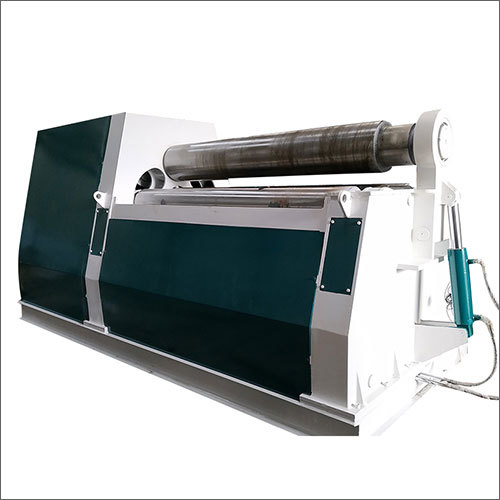

Plate Rolling Machine, Hydraulic Pre-Pinch Type 3 and 4 Rolls

1840000 INR/Unit

Product Details:

- Accuracy High

- Noise Level Low

- Features Pre-Pinch Type Suitable for 3 and 4 Rolls

- Frame Type Robust Steel Frame

- Operating Temperature Standard

- Lubricating System Automatic

- Voltage Standard Industry Voltage

- Click to view more

X

Plate Rolling Machine, Hydraulic Pre-Pinch Type 3 and 4 Rolls Price And Quantity

- 1 , , Unit

- 1840000 INR/Unit

Plate Rolling Machine, Hydraulic Pre-Pinch Type 3 and 4 Rolls Product Specifications

- Customizable

- Automatic

- Varies by Model

- Electric

- Plate Rolling Machine

- Standard

- Hydraulic Power Horsepower (HP)

- Metalworking Machine

- Standard Industry Voltage

- Low

- Automatic

- Pre-Pinch Type Suitable for 3 and 4 Rolls

- 1 Year

- Hydraulic

- Hydraulic

- Robust Steel Frame

- Metal Sheet Rolling

- High Hydraulic Pressure

- High

- White and Green

- Painted

Plate Rolling Machine, Hydraulic Pre-Pinch Type 3 and 4 Rolls Trade Information

- Ex-Ahmedabad

- Letter of Credit (L/C)

- 3 , , Unit Per Month

- 30 Days

- Standard Plastic Packing

- Asia, Middle East, Africa

- All India

Product Description

Hydraulic Pre-Pinch Type Plate Rolling Machine that we are offering is popularly known among our customers owing to its superior design and high build quality. This rolling machine is capable of withstanding impacts, heavy loads, and tough conditions. It does not degrade in quality or become inferior in the long run. 3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine is easy to use and maintain. It comes in a plethora of technical specifications.

Specification

|

Voltage |

220-240 V |

|

Brand |

VIRAAT |

|

Automation Grade |

Automatic |

|

Raw Material |

MS AND SS |

|

Phase |

3 PHASE |

|

Machine Type |

Cold Rolling Mill |

|

Rolled Shape |

Tube |

|

Frequency |

50 Hz |

|

Production Capacity |

15-20 ton/day |

|

Country of Origin |

Made in India |

i

Advanced Hydraulic Performance

This plate rolling machine integrates advanced hydraulic systems to deliver high pressure and precise sheet forming. The pre-pinch type mechanism allows for accurate alignment of materials, reducing reworks and increasing efficiency. Its robust steel frame ensures durability, while the automatic lubricating system minimizes maintenance demands for seamless operation.

Tailored to Industrial Needs

Designed for versatility, the machine accommodates customizable dimensions and offers both 3-roll and 4-roll models. With low noise output and standard industry voltage compatibility, it fits seamlessly into various manufacturing environments. The surface is painted for added protection, while the automated control system enhances user convenience and operational safety.

FAQ's of Plate Rolling Machine, Hydraulic Pre-Pinch Type 3 and 4 Rolls:

Q: How does the hydraulic pre-pinch mechanism improve plate rolling?

A: The hydraulic pre-pinch mechanism precisely aligns and grips the metal sheet before rolling, minimizing slippage and ensuring consistent bends. This technology reduces material wastage and allows for greater accuracy in the shaping process.Q: What types of metal sheets can the machine process?

A: This plate rolling machine is suitable for a wide range of metal sheets, including steel, stainless steel, aluminum, and other alloys commonly used in fabrication and manufacturing industries.Q: When should I choose a 3-roll versus a 4-roll configuration?

A: A 3-roll machine is ideal for standard rolling tasks, while a 4-roll model offers more versatility and can handle more complex shapes, providing easier pre-bending and consistent results for thicker or larger sheets.Q: Where is this machine typically installed and operated?

A: The machine is designed for installation in industrial factories, metal fabrication workshops, and manufacturing facilities where metal sheet rolling is a key part of production processes.Q: What is the process for customizing dimensions and specifications?

A: Customers can specify length, width, and height requirements during ordering. As a manufacturer and exporter, we work closely to deliver machines tailored to your operational space and production needs.Q: How does the automatic lubricating system benefit usage?

A: The integrated automatic lubricating system ensures continual, precise lubrication of moving parts, reducing wear and tear, extending machine lifespan, and enhancing operational smoothness without frequent manual maintenance.Q: What warranty and after-sales support are provided?

A: Each machine comes with a 1-year warranty covering manufacturing defects. Comprehensive after-sales service and technical support are available to ensure optimal performance and quick resolution of any issues.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email