- Home Page

- Company Profile

-

Our Products

- Plate Rolling Machine

- Shearing Machine

- Hydraulic Press

- Metal Sheet Straightening Machine

- Hydraulic Press Brake Machine

- Sheet Straightening Machine

- Industrial Machinery

- Plate Straightening Machine

- Plate Bending Machine

- Hydraulic with Pre Pinching type Plate Rolling Machine

- Mechanical Plate Rolling Machine

- Sheet Rolling Machine

- 3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine

- Fully Hydraulic Pre-Pinching Type Plate Rolling Machine

- Semi Hydraulic Plate Bending Machine

- 3 Phase Stainless Steel Plate Rolling Machine

- Hydraulic 3 And 4 Roll Plate Bending Machine

- Hydraulic Plate Bending Machine

- SHEET ROLLING MACHINE

- Our Clients

- Contact Us

Plate Bending Machine

450000.0 INR/Unit

Product Details:

- Application Sheet Metal Fabrication, Automotive Industry, HVAC Industry, Heavy Engineering

- Automation Grade Hydraulic and NC

- Usage Industrial

- Size Standard

- Product Type Plate Bending Machine

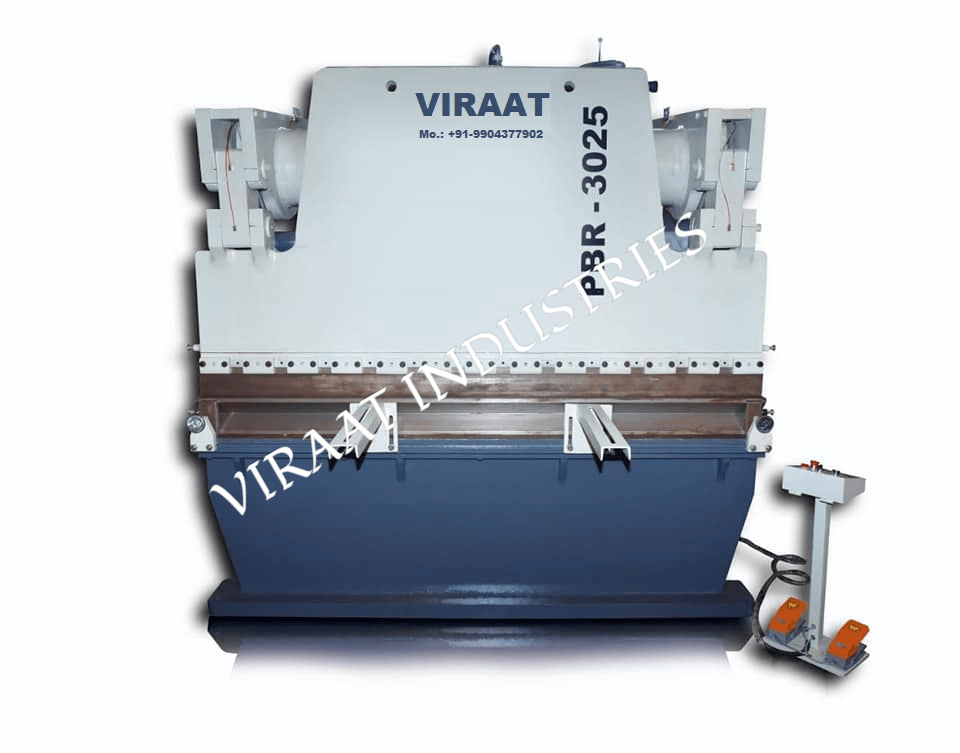

- Color Blue & White

- Width 1000-5000 Millimeter (mm)

- Click to view more

X

Plate Bending Machine Price And Quantity

- 450000.0 INR/Unit

- 1 Unit

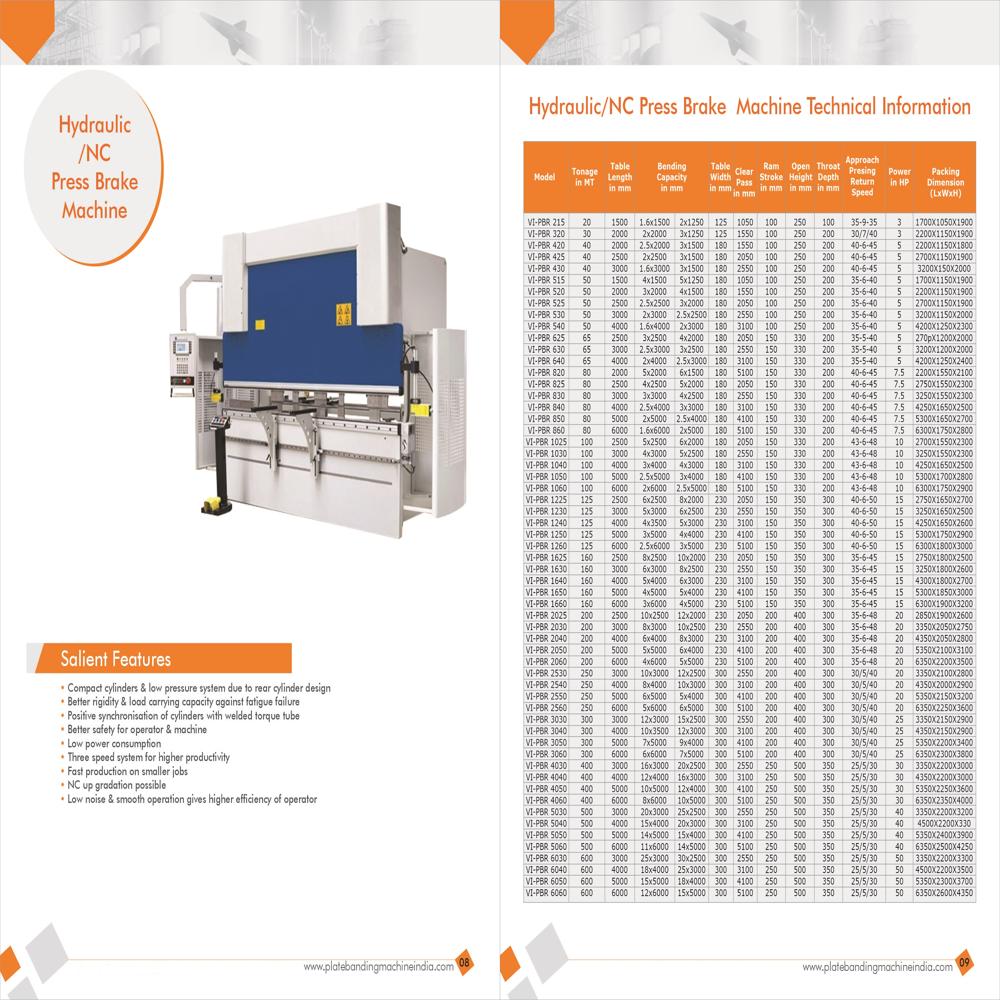

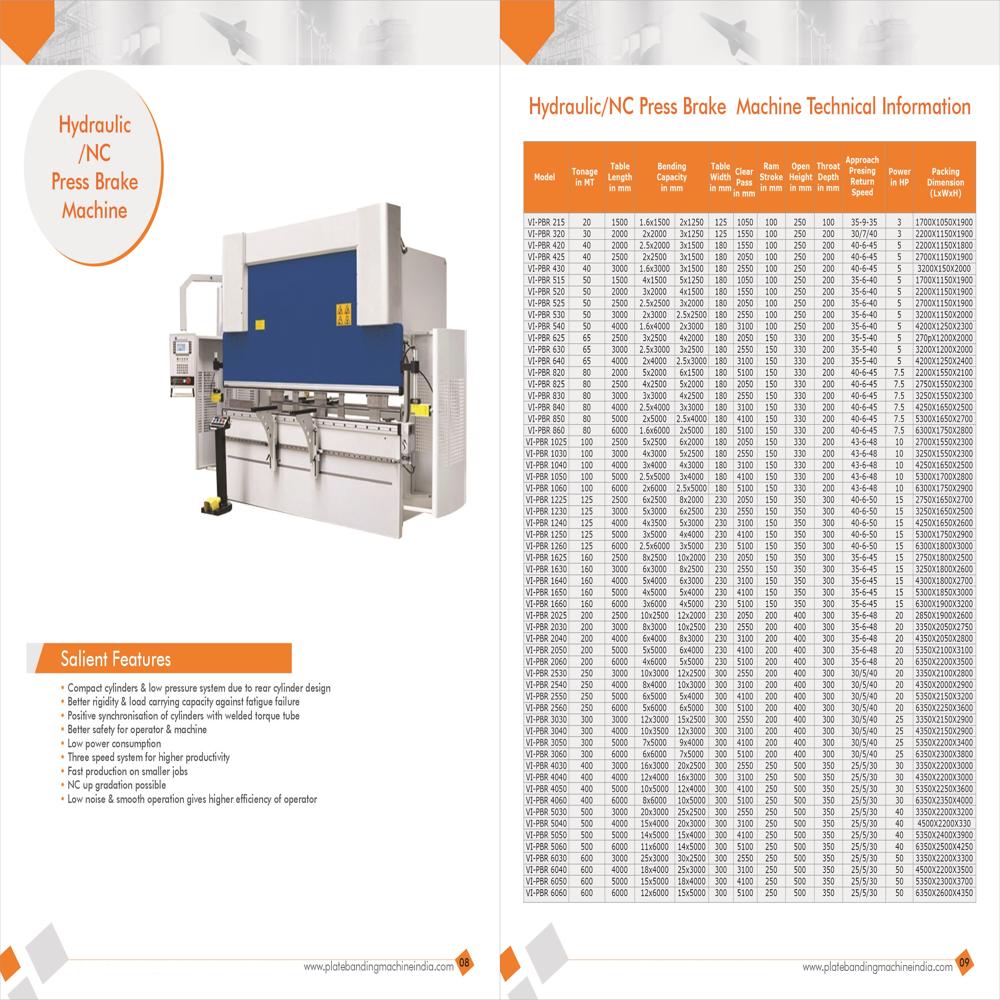

Plate Bending Machine Product Specifications

- Plate Bending Machine

- Standard

- Industrial

- Sheet Metal Fabrication, Automotive Industry, HVAC Industry, Heavy Engineering

- Hydraulic and NC

- Blue & White

- 1000-5000 Millimeter (mm)

Plate Bending Machine Trade Information

- 100 Unit Per Month

- 10 Days

Product Description

A Hydraulic Press Brake Machine is a high-precision metal forming machine used for bending and shaping sheet metal and metal plates with accuracy and consistency. Powered by advanced hydraulic systems, this machine applies controlled force to bend materials such as mild steel, stainless steel, aluminum, and other alloys into desired angles and shapes.

Hydraulic press brakes are widely used in metal fabrication industries, automotive manufacturing, construction, electrical enclosures, and heavy engineering applications. They offer superior bending accuracy, smooth operation, and high repeatability compared to mechanical press brakes. Modern hydraulic press brake machines are equipped with CNC or NC control systems, ensuring precise positioning, faster setup times, and reduced material waste.

Designed for durability and efficiency, hydraulic press brake machines feature robust frames, synchronized hydraulic cylinders, adjustable back gauges, and safety systems for operator protection. They are ideal for producing complex bends, channels, brackets, cabinets, panels, and structural components.

With high productivity, low maintenance requirements, and excellent bending quality, hydraulic press brake machines are an essential solution for professional sheet metal bending operations.

Engineered for Versatile Industrial Applications

This Plate Bending Machine is purpose-built for diverse sectors, including sheet metal fabrication, automotive manufacturing, HVAC component production, and heavy engineering tasks. Its range of width capacities and high-grade automation accommodate varied project requirements, making it an indispensable asset for workshops and industrial facilities alike.

Precision Automation for Reliable Performance

Featuring both hydraulic and NC automation grades, our machine assures precise control, uniform bends, and improved operational efficiency. This technology not only optimizes productivity but also ensures safety and ease of use for operators across different industrial backgrounds.

FAQ's of Plate Bending Machine:

Q: How does the hydraulic and NC automation enhance plate bending operations?

A: Hydraulic and NC automation on this machine provide controlled, repeatable pressure and angle adjustments, ensuring consistently accurate bends. This helps reduce operator fatigue and minimizes material waste, streamlining the plate forming process for greater productivity.Q: What materials and thicknesses can the Plate Bending Machine handle?

A: The machine is designed for industrial use, capable of bending a variety of sheet metals commonly used in applications like automotive, HVAC, and heavy engineering. The width capacity ranges from 1000 to 5000 mm, making it suitable for both standard and larger sheets.Q: When is it recommended to use this machine over manual bending tools?

A: This machine is best suited for high-volume or precision projects that require uniform bends across larger sheets or thicker materials. Its automation features ensure consistent results, which are hard to achieve with manual bending tools in industrial settings.Q: Where is the Plate Bending Machine most effectively utilized?

A: Its applications span sheet metal fabrication workshops, automotive parts manufacturing, HVAC duct production, and heavy engineering plants. Any facility requiring high-quality, repeatable metal bends can benefit from this equipment.Q: What is the operational process involved in using this plate bending machine?

A: The process typically involves loading the metal sheet, setting the required dimensions and bend angles on the NC or hydraulic control, and initiating the bending cycle. Automation ensures precise execution, while safety systems protect the operator throughout the procedure.Q: How does this machine benefit industrial operations?

A: By automating the bending process, it reduces manual labor, increases throughput, and delivers precise, repeatable results. This minimizes errors, optimizes material use, and provides a safer working environment for operators.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email