- Home Page

- Company Profile

-

Our Products

- Plate Rolling Machine

- Shearing Machine

- Hydraulic Press

- Metal Sheet Straightening Machine

- Hydraulic Press Brake Machine

- Sheet Straightening Machine

- Industrial Machinery

- Plate Straightening Machine

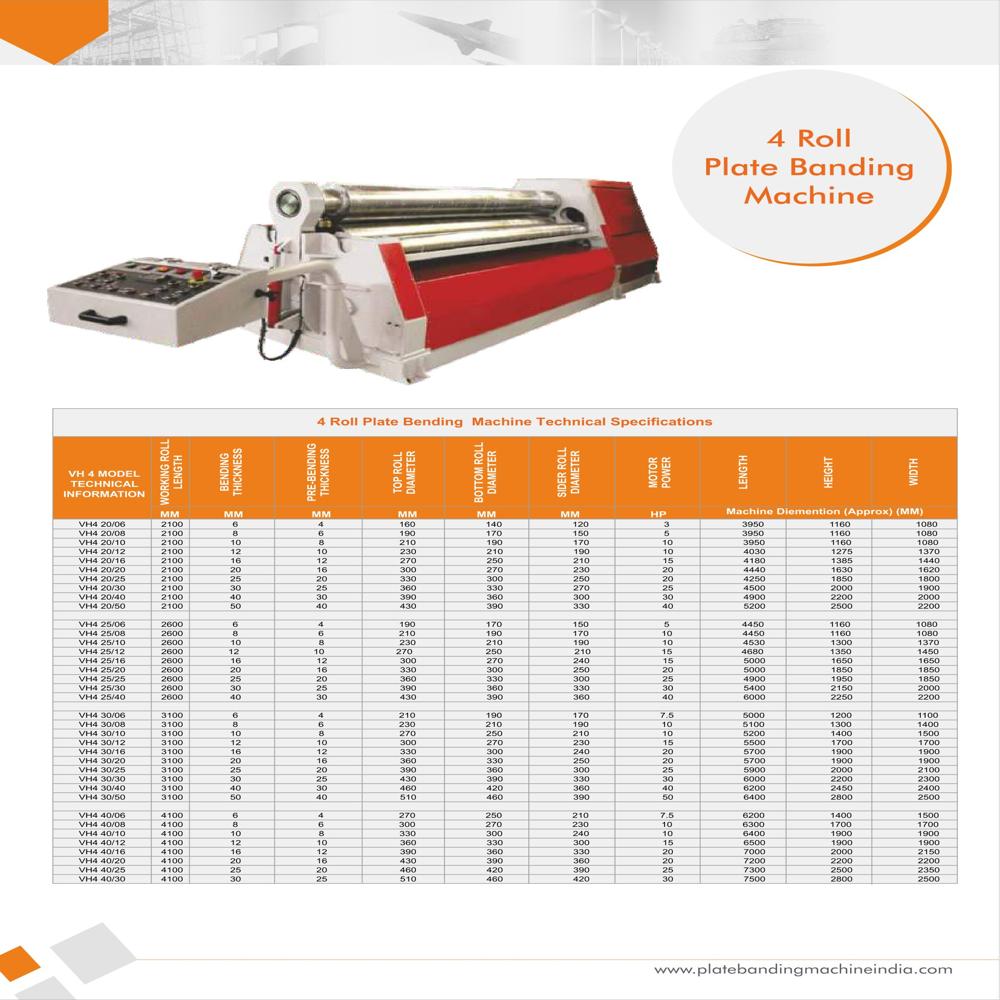

- Plate Bending Machine

- Hydraulic with Pre Pinching type Plate Rolling Machine

- Mechanical Plate Rolling Machine

- Sheet Rolling Machine

- 3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine

- Fully Hydraulic Pre-Pinching Type Plate Rolling Machine

- Semi Hydraulic Plate Bending Machine

- 3 Phase Stainless Steel Plate Rolling Machine

- Hydraulic 3 And 4 Roll Plate Bending Machine

- Hydraulic Plate Bending Machine

- SHEET ROLLING MACHINE

- Our Clients

- Contact Us

3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine

1850000.0 INR/Unit

Product Details:

X

3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine Price And Quantity

- 1850000.0 INR/Unit

- 1 Unit

3 and 4 Rolls Hydraulic Pre-Pinch Type Plate Rolling Machine Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- Australia, Central America, Western Europe, Middle East

- All India

Product Description

3 Roll Hydraulic Pre-Pinch Type Plate Rolling Machine is a high precision machine designed and developed in our state-of-the-art production site making the best use of pioneering in-house tools and techniques. This rolling machine is typically used in industries including mechanical, metalworking, manufacturing, among others. It is used to compress and form a metal sheet. 3 Roll Hydraulic Pre-Pinch Type Plate Rolling Machine can be purchased from us at a budget-friendly price.

Specification

|

Material |

Metal |

|

Brand |

Viraat |

|

Production Capacity |

3-6 ton/day |

|

Phase |

Three Phase |

|

Warranty |

12 Months |

|

Weight |

12000 Kgs |

Precision Plate Rolling for Industrial Needs

Engineered for high-demand industrial applications, this machine combines hydraulic power with precision laser technology for superior plate bending. Its pre-pinch design facilitates accurate alignment, minimizing errors and material waste, while the painted surface treatment boosts corrosion resistance.

Reliable and Long-Lasting Performance

With a 5-year warranty and a rugged build, this plate rolling machine offers dependable operation for continuous industrial use. The semi-automatic controls streamline workflow, making it suitable for frequent, repetitive tasks in manufacturing environments.

FAQ's of 3 Roll Hydraulic Pre-Pinch Type Plate Rolling Machine:

Q: How does the pre-pinch function enhance the plate rolling process?

A: The pre-pinch mechanism holds the metal plate firmly in position before the main rolling process begins, ensuring precise feeding and minimizing slippage or misalignment, which leads to more accurate bends and efficient material handling.Q: What are the primary applications of the 3 Roll Hydraulic Pre-Pinch Plate Rolling Machine?

A: This machine is primarily used in heavy fabrication industries, such as tank manufacturing, shipbuilding, and construction, for shaping and bending metal plates into cylindrical or curved forms.Q: When should maintenance be performed on this plate rolling machine?

A: Routine maintenance is recommended at regular intervals based on usage intensity, typically including checks of hydraulic systems, electrical components, and lubrication, to ensure optimal performance and longevity.Q: Where is this machine manufactured and exported from?

A: The 3 Roll Hydraulic Pre-Pinch Plate Rolling Machine is manufactured and supplied by a leading Indian exporter, manufacturer, service provider, and supplier, serving clients across domestic and international markets.Q: What benefits does the 5-year warranty offer to users?

A: The 5-year warranty provides users with peace of mind, covering manufacturing defects and ensuring long-term support for parts and service, which reduces operational downtime and maintenance costs.Q: How does the laser technology improve the operation of this plate rolling machine?

A: Laser technology enhances precision during the rolling process, allowing for finer control over measurements and reducing errors, resulting in consistently high-quality rolled products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email